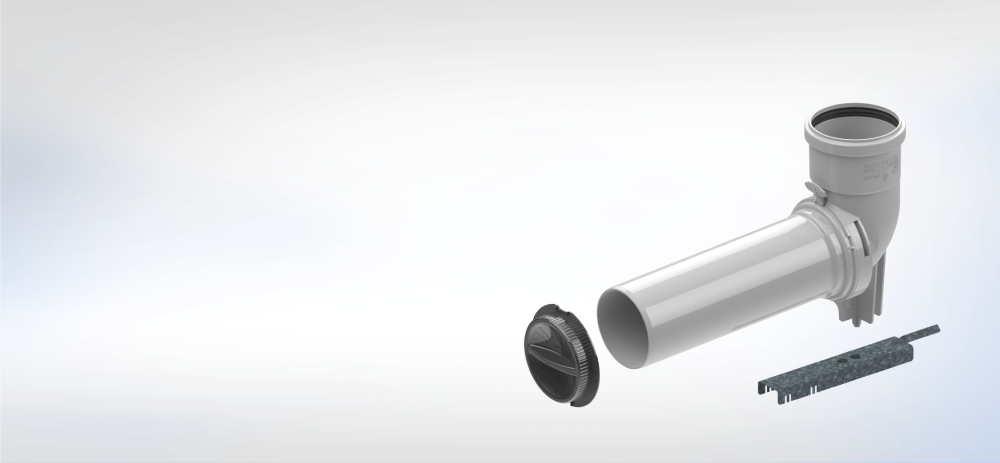

Short bend

We focus on quality, innovation and customised solutions.

The D80 short bend from Skoberne - the solution for particularly narrow shafts

With an external dimension of 118 mm, the D80 short bend from Skoberne can be lowered into the shaft from above together with the flue gas pipe. This means that the chimney connection no longer has to be cut open over a large area and laboriously closed again in order to install the support elbow. In addition, the short bend is suitable for leaving existing stainless steel or ceramic pipes in the shaft and using them as air supply ducts, which is a significant cost advantage during renovation.

The horizontal connection pipe is connected to the elbow element as usual from the installation room. The two components are connected using a special bayonet catch, which reliably prevents unintentional loosening. The components can only be separated again by pressing the release button. When lowering into the shaft, the Skoberne protective cover supplied is placed on the curved element. It protects the bayonet on the short bow from damage and dirt.

Advantages of the Skoberne D80 short bow at a glance:

- Particularly small external dimensions of only 118 mm

- Suitable for shafts and chimney liner pipes made of stainless steel or ceramic from 120 mm internal dimension

- For flue gas pipe D80

- Insertion of the elbow element together with the flue gas pipe from above through the shaft

- No extensive opening or drilling of the shaft or chimney liner, no time-consuming sealing of the connection

- Two versions of the support rail for standard installation or for renovation with chimney liner or alternatively with special adapter for quick and easy installation without support rail

- Secure connection thanks to bayonet lock

- Proven Skoberne double lip seal made of EPDM

Short bend from Skoberne: Simple installation in existing systems

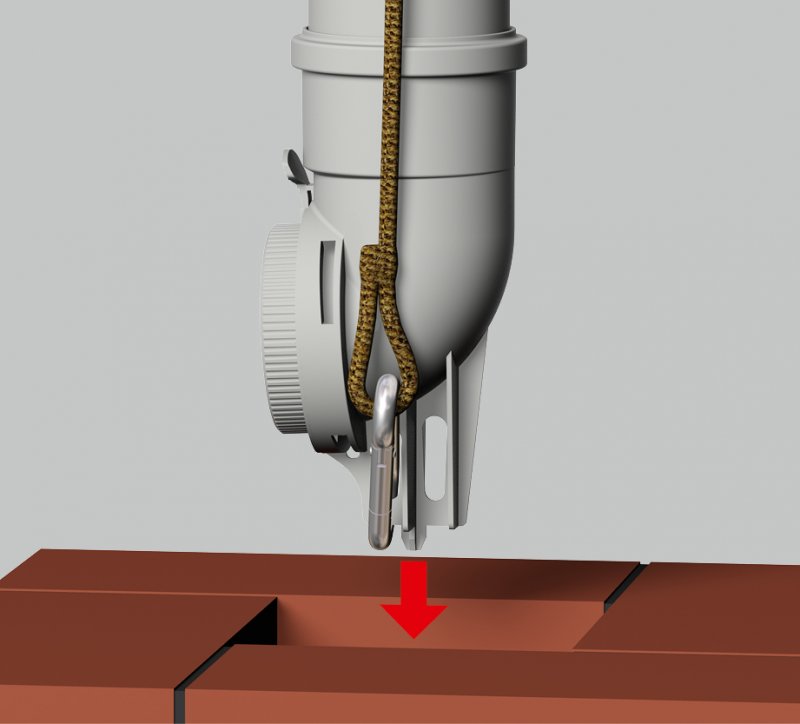

Installation step 1

The vertical elbow element is installed starting from the outlet. It is lowered into the shaft or the existing pipe from above together with the vertical flue gas pipe. The opening of the short bend is closed with a protective cover. A pull-in aid prevents the sockets of the flue gas pipe from being pulled apart during lowering. The cable of the pull-in aid is fastened in eyelets at the bottom of the short bend and kept taut during lowering.

Installation step 2

The vertical flue gas pipe and the bend element of the short bend are lowered into the shaft or the existing pipe and placed on the previously installed support rail. The support rail is installed in the shaft with the standard rail or in the existing stainless steel or ceramic pipe with the short stainless steel rail. Alternatively, the practical adapter can be used, which is quickly and easily lowered into the shaft or the existing pipe together with the flue gas pipe using a PP pipe with or without a socket.

Installation step 3

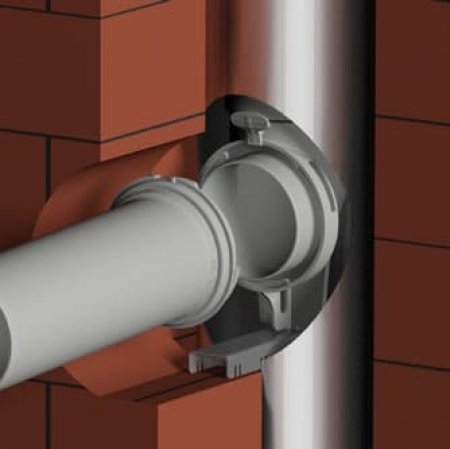

The protective cover is removed from the short elbow through the existing flue pipe opening. The horizontal connecting pipe is then inserted into the elbow element.

By turning the bayonet catch clockwise, the connecting pipe is locked to the short elbow. This creates a connection between the two elements that is secured against unintentional loosening.

Installation step 4

The connection to the heat generator is then made using the tried and tested Skoberne connection pipes.