Unifix LA90

UNIFIX LA90

Further information is available for download:

The approval of the respective

flue gas system manufacturer provides

information on design and

use.

UNIFIX shaft moulding blocks are a UNIversal miracle. AAs an LA 90 shaft, they are suitable both for accommodating flue gas pipes and as a fire protection casing for solid fuels.

"FIX" is synonymous with speed and ease of installation.

Flexible and universal in planning and processing

The UNIFIX building material at a glance

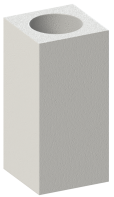

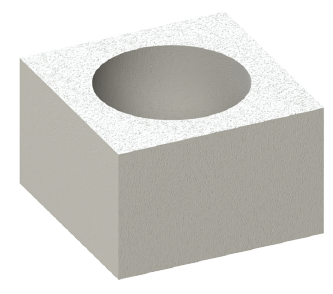

UNIFIX shaft moulded blocks are made of steam-hardened aerated concrete with an average bulk density of 0.5 kg/dm³ and are therefore particularly lightweight. Cut-outs can be carried out with standard tools to save energy. The shaft moulding blocks have a square outer dimension and a round central hole. They are simply bonded with thin-bed mortar.

The UNIFIX blocks are approved both for the construction of "assembly chimneys" and for the construction of shafts for flue gas pipes, as they have general building authority approval as a shaft and as a chimney. They also offer a fire resistance period of 90 minutes.

The shaft is available in five standard sizes and covers an enormous range for different

applications.

|

|

UNIFIX 165Shaft for plastic flue gas pipes |

|

|

|

|

|

|

System description:

UNIFIX LA90

- Certification: Z-7.4-3048

- Material: Aerated concrete

- Fire resistance class: LA9

Universally applicable:

- Use of condensing technology (up to T160) or solid fuel technology (up to T 400)

- Fire resistance duration: 90 minutes

- Small external dimensions

- Five standard sizes enable simple storage and safe calculation

UNIFIX 165: 240 x 240 x 500 mm

UNIFIX 210: 300 x 300 x 250 mm

UNIFIX 240; 360 x 360 x 250 mm

UNIFIX 280: 400 x 400 x 250 mm

UNIFIX 325: 450 x 450 x 250 mm - Generally tested and approved by building authorities

Quick and easy to assemble:

- Shaft element height up to 500 mm

- Lightweight aerated concrete - up to 75 % weight saving

- Easy to work on site with standard tools

- Simple bonding with thin-bed mortar

- Easy to realise roof penetration

Area of application:

- Cascade systems (up to T120)

- Multiple occupancy (up to T120)

- Condensing technology (up to T 160)

- Solid fuel technology (up to T 400)